Flapper Style

Drill Pipe Float Valve

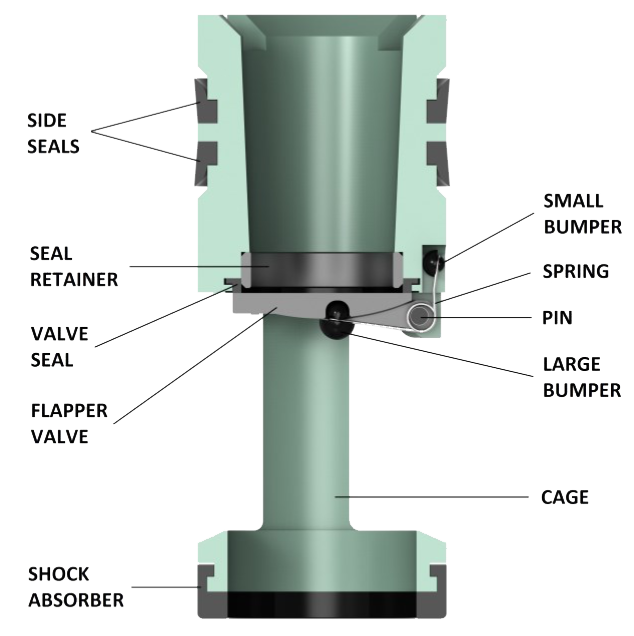

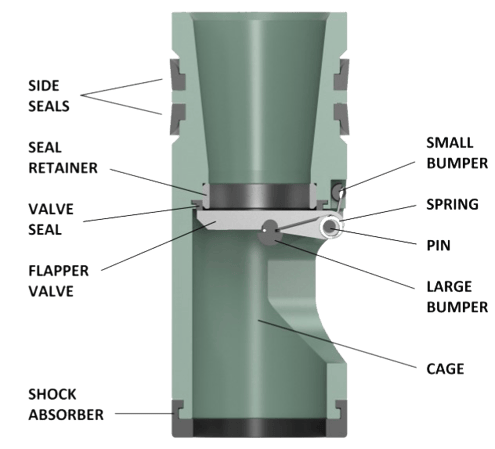

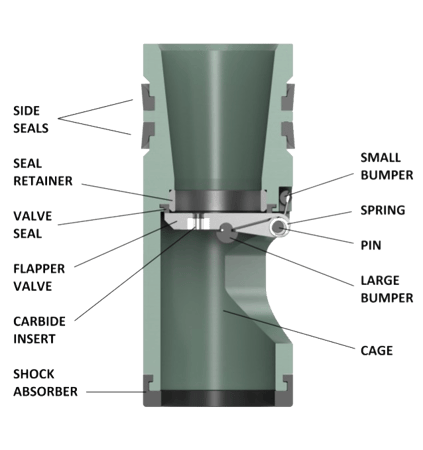

Model G - Flapper Type-Standard

The Model G is a flapper-type float valve that, when opened, offers an unobstructed bore through the float valve. The uniquely designed flapper closes rapidly to prevent shavings from entering the drill string when circulation stops and also assists primary BOP equipment in maintaining internal pressure control. The valve will fully open when the first joint is raised from the hole, preventing pulling wet joints.

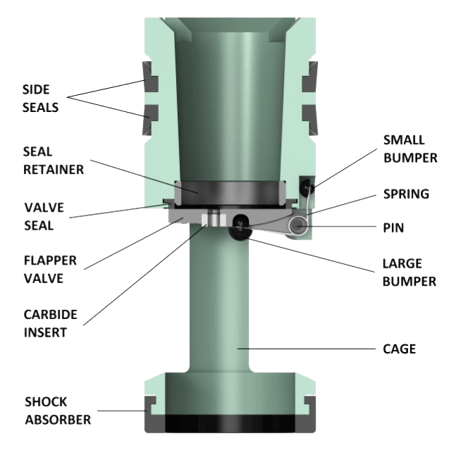

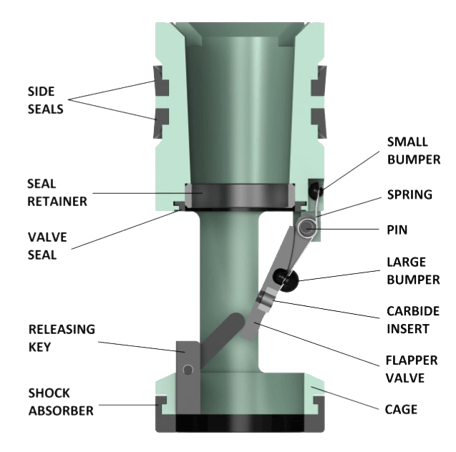

Model GA - Flapper Type-Pressure Monitoring

The Model GA Pressure-Monitoring flapper-type float valve is indistinguishable from the Model G with the exception of a tungsten-carbide insert in the flapper valve.

The insert has a quarter-inch orifice through the center that allows for differential pressure monitoring. The orifice also allows for partial automatic filling of the drill pipe during run in.

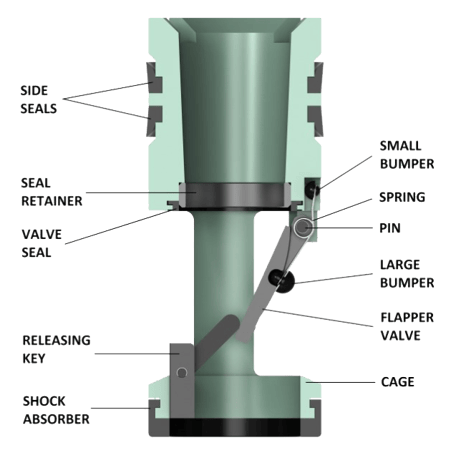

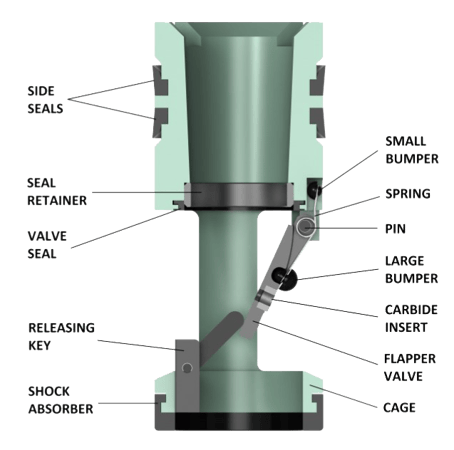

Model GC - Flapper Type-Automatic Fill

The Model GC Automatic-Fill flapper-type float valve incorporates a unique self-releasing key assembly that holds the flapper partially open during run in, allowing the pipe to fill from the bottom. This eliminates the need for filling the drill pipe from the top, saving time and money.

The valve will fully open when the first joint is raised from the hole, preventing pulling wet joints while avoiding the environmental and safety risks related to having mud on the rig floor. The valve can be run with the automatic-fill option or in the standard, closed position.

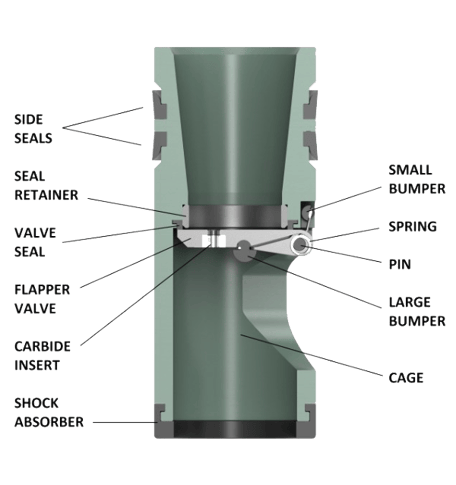

Model GCA - Automatic-Fill/Pressure-Monitoring

The Model GCA Automatic-Fill/Pressure-Monitoring flapper-type float valve includes all the advantages of the Models G, GC, and GA.

An unobstructed bore through the float valve, when open, permits automatic partial filling of the drill pipe from the bottom and measuring differential pressures when necessary.

Model GS - Flapper Type-High Flow Wells

The Model GS is a flapper-type float valve designed for high flowing corrosive wells. The cage is designed to maximize the amount of flow possible through it, while maintaining its rated pressure.

The GS valve uses a unique flapper made with a relief groove backed by a safe-guard pocket, protecting the pin and spring from excessive wear that can be caused by harsh-corrosive drilling environments. The GS are also stackable, allowing you to run two valves simultaneously.

Model GAS - High Flow Pressure Monitoring

The Model GAS is a flapper-type float valve designed for high flowing corrosive wells and Pressure-Monitoring.

The GAS is indistinguishable from the GS with exception of a tungsten-carbide insert in the flapper valve. The orifice also allows for partial automatic filling of the drill pipe during run in.

Model G-10 – 10,000 PSI

The Model G-10 are flapper type float valves that, when opened, offers an unobstructed bore through the float valve.

The uniquely designed flapper closes rapidly to prevent shavings from entering the drill string when circulation stops and also assists primary BOP equipment in maintaining internal pressure control. The valve will fully open when the first joint is raised from the hole, preventing pulling wet joints.

Model G-15– 15,000 PSI

The Model G-15 are flapper type float valves that, when opened, offers an unobstructed bore through the float valve.

The uniquely designed flapper closes rapidly to prevent shavings from entering the drill string when circulation stops and also assists primary BOP equipment in maintaining internal pressure control. The valve will fully open when the first joint is raised from the hole, preventing pulling wet joints.

Size Chart and Installation

We've got the perfect size chart and installation steps for you.