Drill Pipe

Float Valves

Keystone Energy Tools

Certified and

Pressure-tested

Drill Pipe

Float Valves

Keystone Energy Tools provides Certified, Pressure-Tested Drill Pipe Float Valves. As a leading manufacturer of drill pipe float valves, we know the severity of drilling with a reliable and trusted float valve; therefore, we offer certified float valves that are serialized. Additionally, we will provide certification of high-and-low pressure tests upon request.

All KET Float Valves, baffle plates, and valve pullers are interchangeable with the Baker® Style Model F, and Baker® Style Model G Float Valves.

Reliable

We proudly produces one of the most reliable Drill Pipe Float Valves on the market today.

Preventative

Designed with the latest in 3D Modeling, our valves allow for a better mating of component parts, in turn reducing the risk of down hole valve failure.

Durable

Our valves are precision manufactured from high-grade materials and perform optimally in drilling environments.

Variety

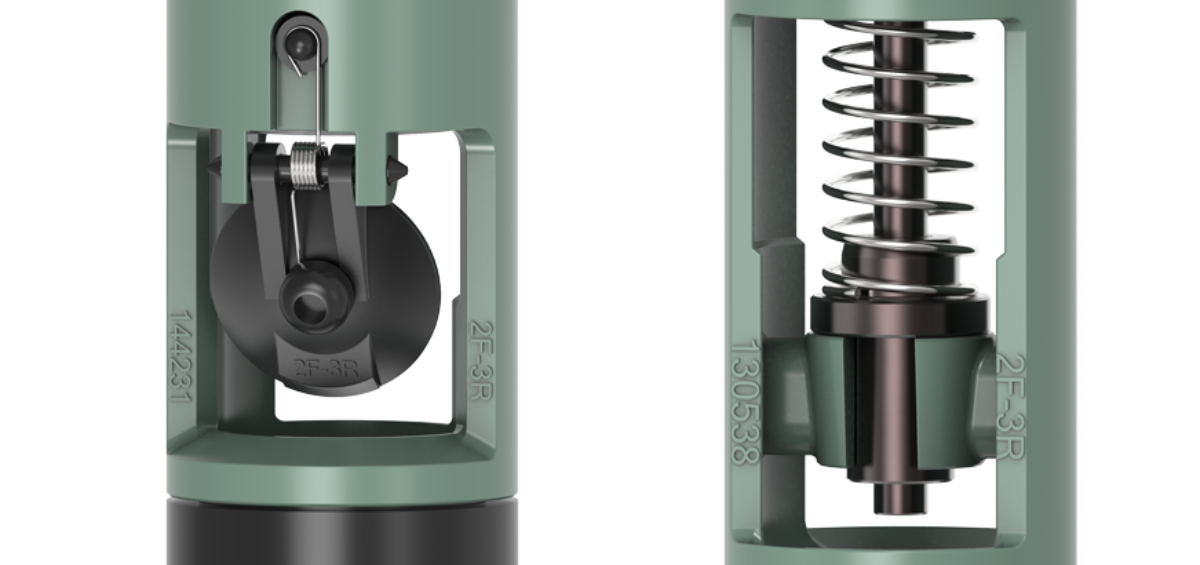

We offer valves for all drilling applications and offer both Plunger-Type Float Valves and Flapper-Type Float Valves.

Valves Built to Last

Drill pipe float valves are essential for drilling, and must stand the test of harsh environments. As such, our cages are cast out of alloy steel specifically for today's increasingly intense drilling environment. This includes:

Heat treating to prevent the corrosive effects of hydrogen-sulfide gas (H2S)

Manufacturing from one-piece casting to produce a superior and more reliable valve body

Offering additional options of stainless steel and Nickel Plated valves to prevent highly corrosive environments

Drill Pipe Float Valves

All KET Float Valves, baffle plates, and valve pullers are interchangeable with the Baker® Style Model F, and Baker® Style Model G Float Valves.

Frequently Asked Questions

-

Why do Baker Drill Pipe Float Valves no longer exist?

The Baker® drill pipe float valve was THE float valve of choice for many years - That’s who originated it and built it first.

By the 1990s, a few other oilfield tools manufacturers started making them. But for many, the Baker® brand was the only one they would use, and Baker® SPD was considered to be the leading manufacturer of drill pipe float valves in the industry. In 2006 Baker Hughes® sold off Baker SPD® and quit making Float Valves.

So there is an education gap there, and we find ourselves explaining to the customer that there IS no Baker® drill pipe float valve any longer.

But there’s good news. The Baker® brand was well-loved due to its quality production and superior engineering, construction, and dependability. And today that quality has been matched—and exceeded— with the Keystone Energy Tools line of float valves.

-

How are the cages manufactured?

Our cages are manufactured for today’s increasingly harsh drilling environment. The cages are cast out of alloy steel and are heat treated to a hardness equal to or less than 22 Rockwell C (≤ 22 Rockwell C 2 HR). Heat treating the valves address the corrosive effects of hydrogen-sulfide gas (H2S) on them. Keystone’s integral valve bodies are manufactured from one-piece casting and are not welded together, contrary to the way some competitors produce theirs. This means that you receive a superior and more reliable valve body.

For highly corrosive environments we offer stainless steel & Nickel Plated valves.

-

How are the plunger valves manufactured?

All plunger valves are machined from one solid piece of material, producing a more reliable float valve and reducing the risk of down hole valve failure. Other leading manufacturers construct their plungers from two separate pieces of material. This produces plungers that are invariably either shrunk fit, screwed, or welded together.

-

What are the flapper valves made of?

Our standard-service flapper valves are made of low-alloy steel and then case hardened for wear resistance, thus giving a longer operating life.

-

What are the available elastomers?

Available elastomers are nitrile butadiene (NBR, Buna-N) and Viton® (fluoroelastomer, FKM)(H2S Applications) and Aflas (steam service)

*Standard Service Buna Nitrile (212 Deg F) Temperature Rating

*Hi-Temp Viton (450 Deg F) Temperature Rating

* H2s Service Viton (450 Deg F) Temperature Rating

* Steam Service Aflas (475 Deg. F.) Temp rating

-

What are the springs made of?

Elgiloy, Inconel® or stainless steel springs come standard on all our valves. These high alloy springs are good for sour gas (H2S) applications. KET springs are significantly more resistant to corrosion in comparison to standard-service springs provided by most other manufacturers.

-

Are the drill pipe float valves and replacement parts interchangeable?

All Keystone drill pipe float valves and replacement parts are manufactured to standard industry dimensions, and are interchangeable with other major manufacturers’ parts.

-

Are the drill pipe float valves available for H2S/High Temp. service?

Available in both F and G models.

-

What is the float valve's operating pressure?

Standard valves – 7,500 PSI working pressure

High-pressure valves – 10,000 PSI working pressure

-

Where can I find a size chart and installation instructions?

You can refer to the following diagrams for dimensions and sizing details.

You can also refer to our installation instructions for details.

More From Our Blog

9 Types of Drill Pipe Float Valves

Finding the best fit for every individual project is important, and the different types go beyond just the split between the F-type plunger valves and the G-type flapper valves.

Here’s a fast primer and reminder on the differences between the types of non-return valves available.

Drill Pipe Float Valve Size Chart and Installation

High-performance drill pipe float valves are crucial for consistent fluid control throughout the drilling process. It is crucial to properly select and install the right Drill Pipe Float Valves.

But don't stress about it, we've got the perfect Drill Pipe Float Valve size chart and installation steps for you.

Baker Drill Pipe Float Valves: They No Longer Exist! Here’s Why

Often, we get calls from rig supply companies saying they need Baker drill pipe float valves.

For these folks, we have good news and bad news.

The bad news: Baker float valves don’t exist anymore. The good news: Keystone makes a Baker®-style valve that improves on the original.